Ergonomic Work Station MWG2000

based on TLH2000 TRANSLYFT lifting table

Less force, more efficiency

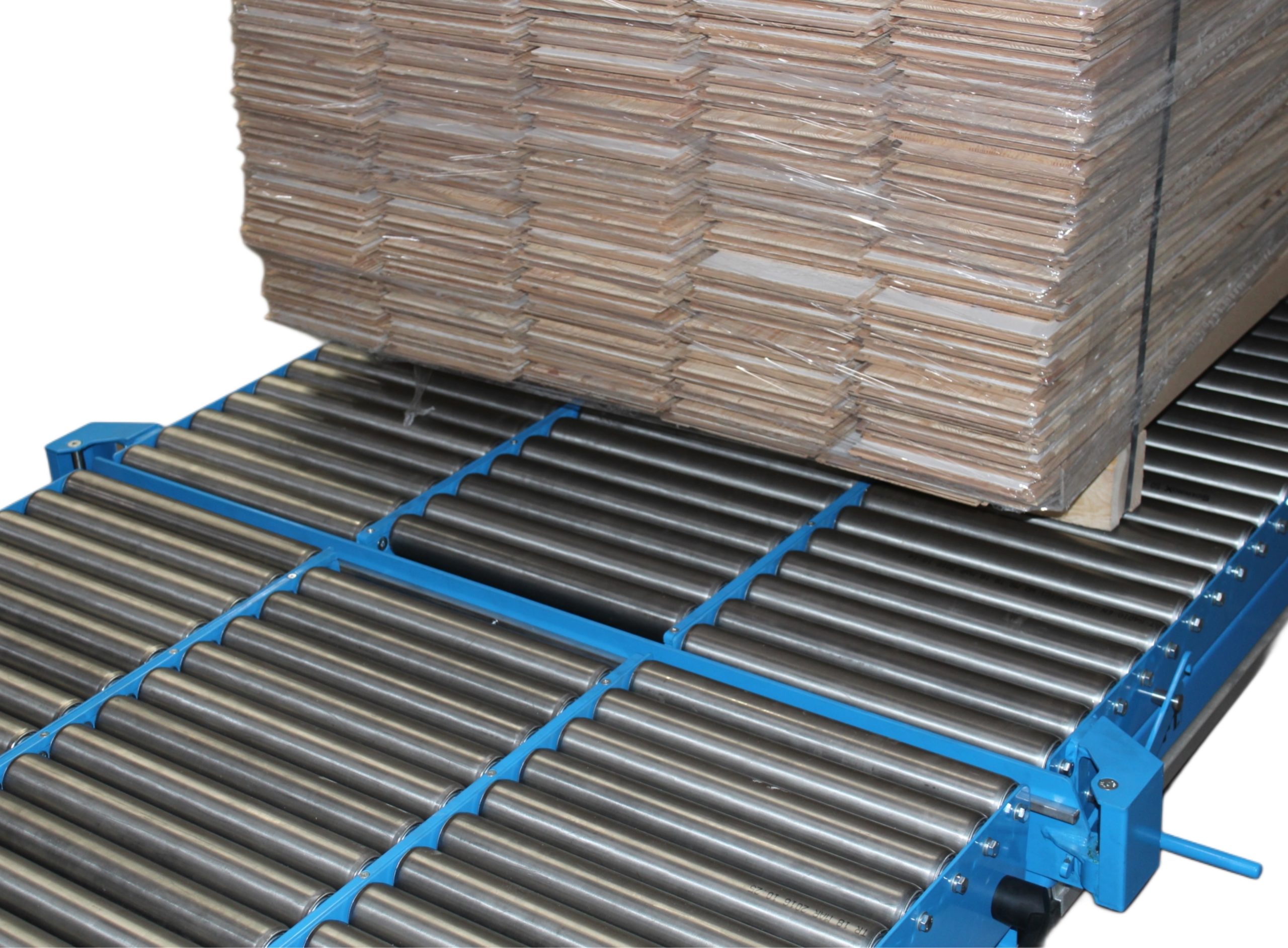

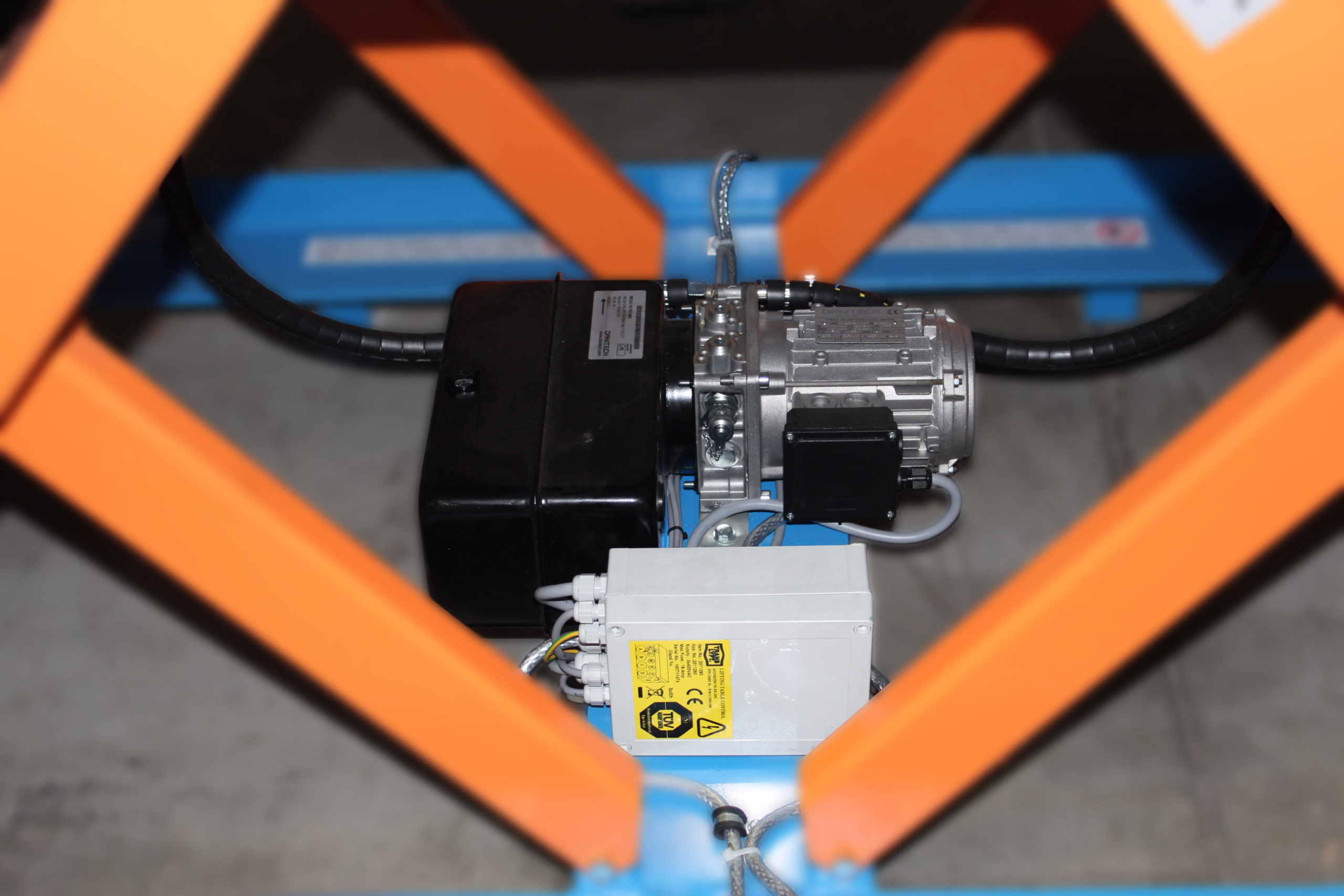

The TLH2000 double-scissor hydraulic lift forms the basis of this semi-manual, ergonomic workstation. Equipped with a specially designed gravity roller conveyor arranged in three rows, it allows for the quick and effortless movement of large and heavy pallets using only the muscle power of even a small operator.

Tailored to the operator's needs

Due to the total length of the system of 7 meters, the station is equipped with a manually raised/lowered bridge, integrated between the lifting table and the buffer - a gravity roller conveyor with a length of over 4 meters. This saves the operator time moving around the workstation.

Product flow optimal performance

The semi-manual system is equipped with a buffer long enough to load 3-4 pallets of product. This buffered volume ensures a smooth workflow, allows the operator to independently regulate their performance and makes it easier for the forklift operator to schedule product deliveries to the system.

Project Details

Client:

Large wooden floors manufacturer

Date:

October 2018

Task:

The task was to design, deliver, install and launch a semi-automatic system enabling the repacking of products from bulk packaging into dedicated individual packaging in the most optimal and ergonomic way.

Project Description

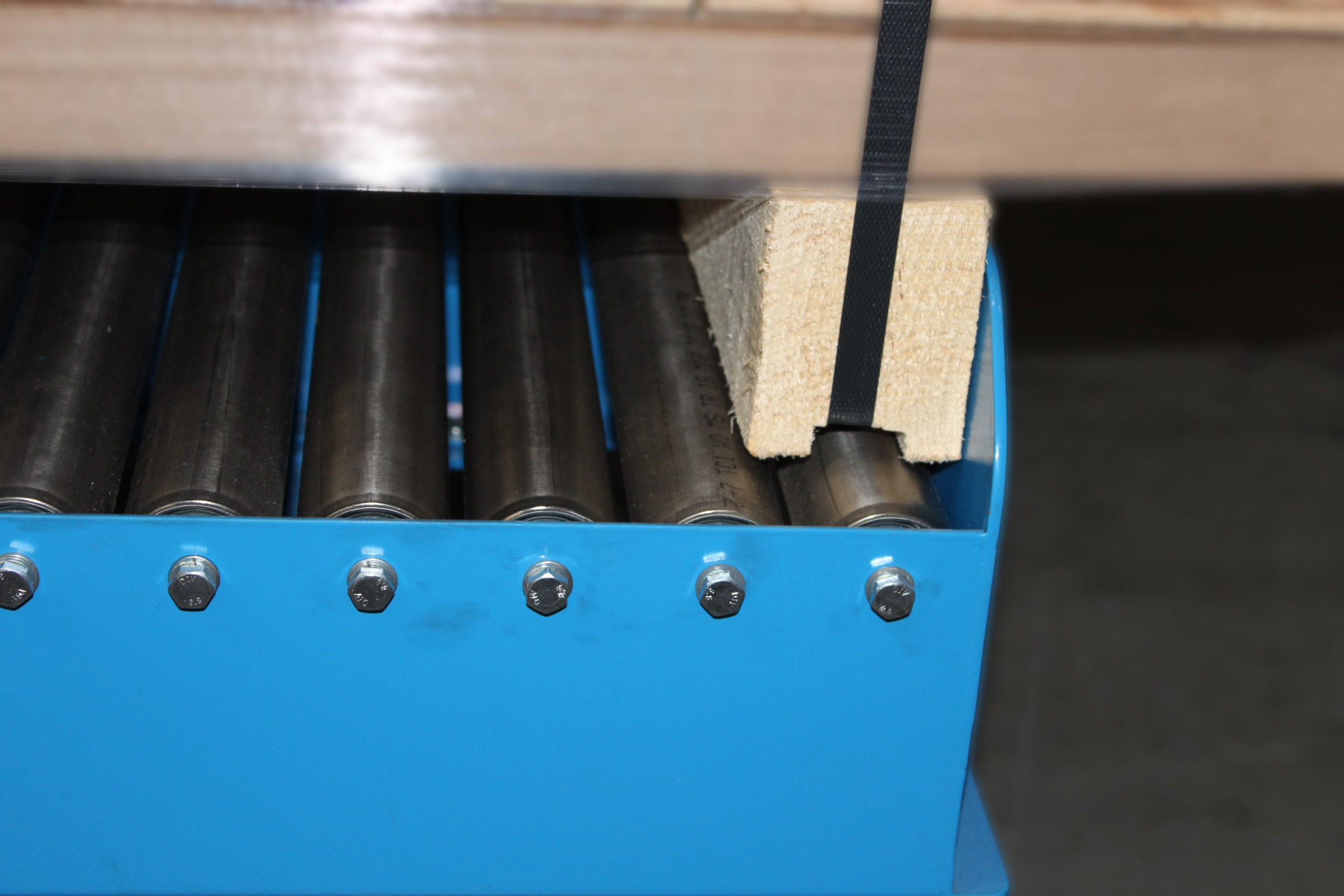

One of the key requirements for achieving this goal was the ability to operate the newly designed system by a single operator. The devices included in the MWG2000 system were selected to ensure that the operator could perform their work without exerting significant physical force and avoiding back strain, while also increasing workstation efficiency and reducing the number of employees involved. The MWG2000 station is based on the TRANSLYFT hydraulic lift, model TLH2000. The key parameters of this double-scissor lift are: closed height: 360mm (280mm lift + 80mm conveyor); stroke: 830mm; maximum lift height: 1190mm; platform size: 2500x1200mm; and lifting time: 36 seconds. A foot-operated control box was used to ensure the operator had full control of the product during the operation and to free their hands for other tasks than handling the product. All conveyors are equipped with three rows of hot-dip galvanised steel rollers with a diameter of 50mm. The rollers are tightly spaced in rows, offset from each other, to enable the smooth transport of various pallet sizes, equipped with various types of bottom feet. Thanks to the tight fit of the rollers, the moving pallet does not bounce or jam. Most importantly, the inertia of the conveyor allows for very easy and effortless movement of heavy pallets across the conveyor surface. Locks at the ends of the conveyor prevent uncontrolled pallet slippage from the conveyor's work area. The central element of the MWG2000 system is the lowering/raising ramp, also equipped with a three-row set of rollers. Assisted by a gas spring, it is easy to operate, even by smaller operators. A manual lock prevents the ramp from uncontrolled raising or lowering. The device is very safe to use. Workstation optimisation also included the use of an ergonomic anti-fatigue mat. We used the Basic Bubble model, a polyurethane version with beveled edges. Thanks to this, the complete MWG2000 station gained a completely ergonomic character. Six weeks after launch, a 15-17% increase in workstation productivity was observed. Operators no longer report lower back pain or lower limb pain. The project was a complete success. The MWG2000 station continues to operate without any issues.